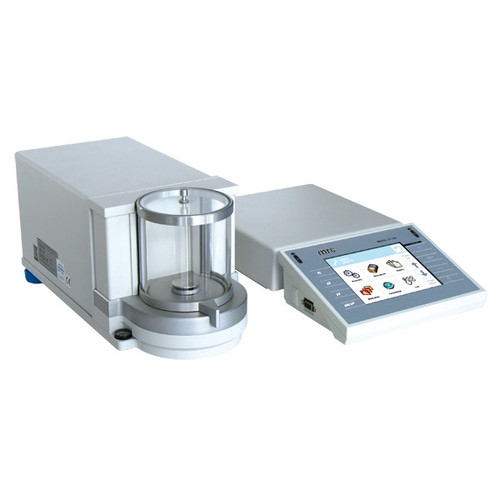

Product Description

The MRC Labs MGB series micro-balance is designed to achieve requirements of mass measurements with ultra-high precision internal calibration ensures measurement reliability and accuracy.

Applications

- Filling,

- Check weighing,

- Percentage,

- Statistics,

- Air buoyancy correction,

- Infrared sensors,

- GLP Procedures.

Features

- Eliminates the electrostatic influence during weighing process,

- Eliminates the temperature influence and separates from vibrations and shocks caused by users operating software,

- Internal automatic calibration,

- Consists of two major parts - an electronic system and a precise mechanical measurement system, kept in a separate closure,

- Made of glass and steel which eliminates the influence of electrostatics on the weighing process,

- Display of 5.7” touch.

Specifications

| Model | MGB-2 | MGB-3 | MGB-5 | MGB-11 | MGB-21 |

| Max Capacity | 2g | 0.8/3g | 5g | 11g | 21g |

| Readability | 1μg | 0.1μg | 1μg | 1μg | 1μg |

| Tare Range | -2g | -3g | -5g | -11g | -21g |

| Repeatability* | 1μg | 1μg | 1.6μg | 2.0μg(to5g) 2.5μ(5g-11g) | 2.0μg(to 5g) |

| Linearity | ±3μg | ±3μg | ±5μg | ±6μg | ±7μg |

| Eccentric Load Deviation | 3μg | 3μg | 5μg | 6μg | 7μg |

| Sensitivity Offset | 1.5 x10-6 x Rt | 3 x 10-6 x Rt | 4 x 10-6 x Rt | ||

| Sensitivity Temperature Drift | 1 x 10-6 °C x Rt | ||||

| Sensitivity Stability | 1 x 10-6 / Rok x Rt | ||||

| Minimum Weight (USP) | 3mg | 3mg | 6.3mg | 6.3mg | 6.3mg |

| Minimum Weight (U=1%, K=2) | 0.2mg | 0.2mg | 0.4mg | 0.4mg | 0.4mg |

| Pan Size | ø6 mm | Ø16mm+Ø60mm (weighing pan for filters) | ø26 mm | ||

| Weight Chamber dimensions | ø90 x 90 mm | ||||

| Stabilization Time | 5 seconds | ||||

| Calibration | Automatic (internal) | ||||

| Working Temperature | +18° - +30°C | ||||

| Change rate of Working Temp. | ±0.3°C/h (±1°C/8hr) | ||||

| Atmospheric Humidity | 45% - 65% | ||||

| Change rate of Atmospheric Humidity | ±1%/h (±4%/8h) | ||||

| Interface | 2xUSB, 2xRS232, Ethernet, 2in/2out (digital) | ||||

| Power supply | 230V / 110V AC | ||||

| Display | 5.7’’ touch screen | ||||

*Repeatability as a standard deviation from 10 weighing cycles.

Touchpad software controls

- Infrared proximity sensors,

- PRINT function,

- TARE function,

- Opening weighing chambers,

- Sensors’ sensitivity adjustment,

- Electronic level indicator,

- ALARM function,

- Graphic level indicator,

- Programmable acceptable tilts.

Weighing Procedures

- Scale Zeroing: Creates new zero point indication, thereby all weights can be measured according to the newly set point,

- Scale Taring: To determine net mass.

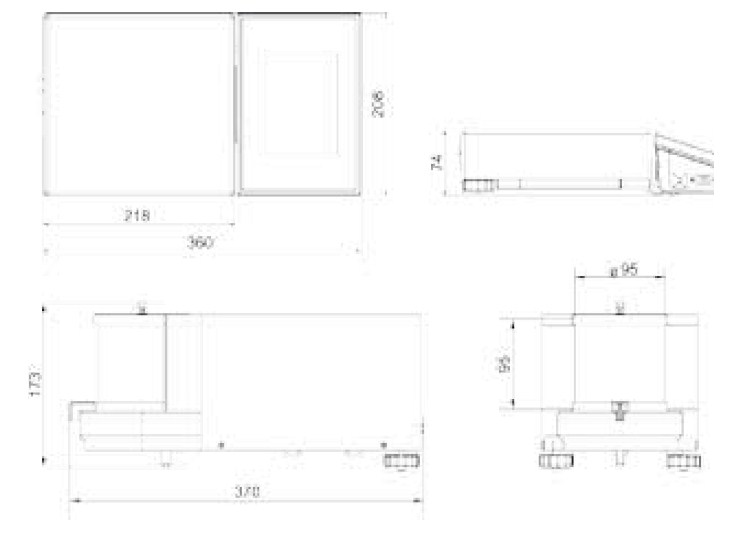

Outer dimensions

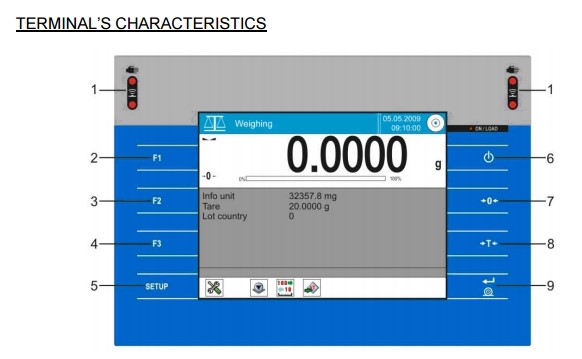

Terminal Characteristics

- Zoom in Sensors: Menu or Button function is assigned with non-touchable sensors (e.g. cabinet door opening , zeroing, printing etc.),

- «F1» button: Moves any application optional menu level to user choosing, profile defining or edition of defined user’s profile,

- «F2» button: Enable Scale Functions like simple weighing, statistics, pieces counting, formulation, percentage weighing and defining density,

- «F3» button: Enables adjusting of internal scale,

- «SETUP» button: Enables main program setting definition,

- «On/OFF» button: Enables switching on/off scale’s LCD display; standby mode,

- «0» button: Enables scale’s indication zeroing,

- «T» button: Enables tarring of container weight which is used during the weighing process,

- «PRINT/ENTER»: Transmit data by interface to external device.

Optional accessories

-

Anti-vibration table - SAL series table designed to perform accurate measurements.

-

Printers - Dual direction thermal print with 8-point head.

-

Printer - CLP Series are thermo transfer printers controlled with optical sensors.

-

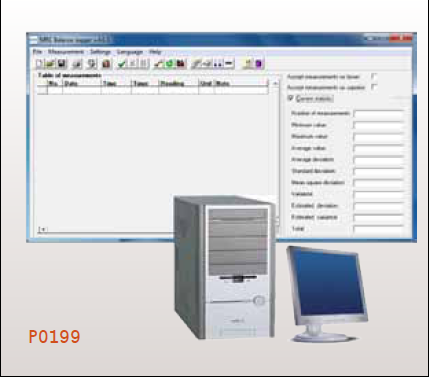

Computer Software - P0199 is designed to collect the measuring data especially from MRC made scales.

Also known as either:

- MRC Lab MRC MGB–2 or MRC MGB2,

- MRC Lab MRC MGB–3 or MRC MGB3,

- MRC Lab MRC MGB–5 or MRC MGB5,

- MRC Lab MRC MGB–11 or MRC MGB11,

- MRC Lab MRC MGB–21 or MRC MGB21.

---

Default Currency

Default Currency

EURO

EURO

ARA - ARGENTINA

ARA - ARGENTINA

AUD - AUSTRALIA

AUD - AUSTRALIA

BRL - BRAZIL

BRL - BRAZIL

CAD - CANADA

CAD - CANADA

CHF - SWITZERLAND

CHF - SWITZERLAND

CLP - CHILE

CLP - CHILE

CNY - CHINA

CNY - CHINA

CZK - CZECH REPUBLIC

CZK - CZECH REPUBLIC

DKK - DENMARK

DKK - DENMARK

GBP - GREAT BRITAIN

GBP - GREAT BRITAIN

IDR - INDONESIA

IDR - INDONESIA

ILS - ISRAEL

ILS - ISRAEL

INR - INDIA

INR - INDIA

JPY -JAPAN

JPY -JAPAN

KRW - SOUTH KOREAN REPUBLIC

KRW - SOUTH KOREAN REPUBLIC

MXN - MEXICO

MXN - MEXICO

MYR - MALAYSIA

MYR - MALAYSIA

NOK - NORWAY

NOK - NORWAY

NZD - NEW ZEALAND

NZD - NEW ZEALAND

PAB - PANAMA

PAB - PANAMA

PHP - PHILIPPINES

PHP - PHILIPPINES

PKR - Pakistan

PKR - Pakistan

PLN - POLAND

PLN - POLAND

RUB - RUSSIA

RUB - RUSSIA

SAR - SAUDI ARABIA

SAR - SAUDI ARABIA

SEK - SWEDEN

SEK - SWEDEN

SGD - SINGAPORE

SGD - SINGAPORE

THB - THAILAND

THB - THAILAND

TRY - TURKEY

TRY - TURKEY

TWD - TAIWAN

TWD - TAIWAN

UAH - UKRAINE

UAH - UKRAINE

ZAR - SOUTH AFRICA

ZAR - SOUTH AFRICA