Product Description

Free Shipping to USA/Canada

MRC PCM-51 Cutting Mill

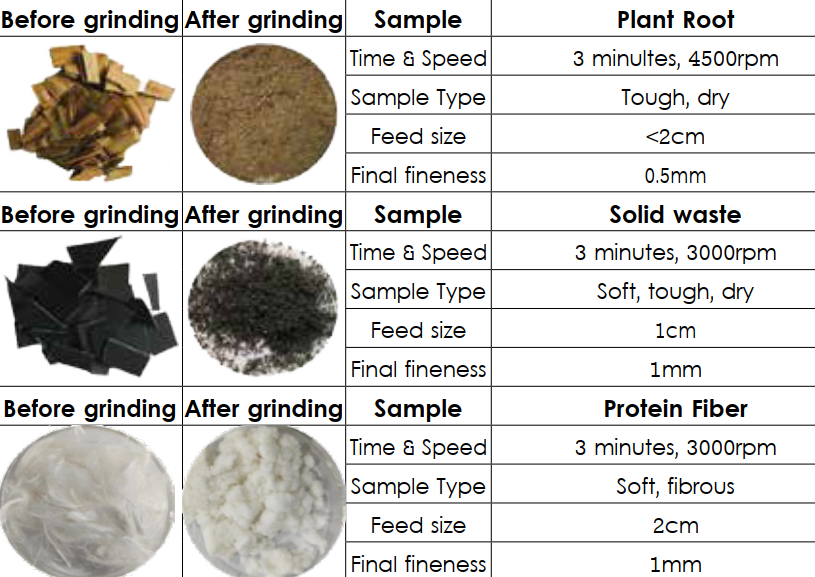

is a high-throughput sample preparation mill with variable speed (500–6000 rpm) for tough, fibrous, and temperature-sensitive materials. It is engineered for rapid, reproducible size-reduction of heterogeneous solids using strong cutting and shearing forces. Samples are fed through an anti-splash hopper into a quick-clean grinding chamber where rotor knives act against cutting bars and a bottom sieve; once particles are smaller than the selected sieve aperture, airflow carries them into a 250 mL collecting bottle. With variable speed from 500 to 6000 rpm, feed size up to <25 mm, and final fineness from ~6.0 mm down to ~0.2 mm (sieve-dependent), PCM-51 handles continuous operation and one-step processing of long, fibrous materials—ideal for RoHS/WEEE sample prep and routine QA/production labs. Tool-less access to rotor, sieve, and hopper simplifies changeovers and cleaning; optional stainless or heavy-metal-free grinding sets support contamination-sensitive workflows.

Applications

Environmental & Waste Testing

- Solid waste, refuse-derived fuel (RDF), municipal waste streams

- RoHS/WEEE heavy-metal sample preparation (PCB fragments, cable jackets)

Polymers & Plastics

- Rubber, engineering plastics, dog chews, elastomers

- Pellets, sprues, cuttings prior to spectroscopy or digestion

Food, Feed & Agriculture

- Grains, seasonings, feed blends

- Straw, stalks, lignite/peat and other plant-based matrices

Materials & General Research

- Paper, wood, brittle composites, bones

- Routine sample prep before digestion, extraction, or imaging

Features

-

Wide particle-size range: select sieves to reach coarse (~6 mm) through fine (~0.2 mm) outputs without pre-crushing.

-

Throughput with control: 500–6000 rpm variable speed optimizes cutting energy for tough vs. heat-sensitive materials.

-

Fast cleaning & changeovers: rotor, bottom sieve, and hopper remove/install easily—minimizing cross-contamination and downtime.

-

Safer operation: electronic safety interlock prevents starts with the door open; anti-splash hopper improves housekeeping.

-

Contamination-aware options: grinding sets available in stainless steel or heavy-metal-free steel for regulated analyses.

-

Continuous processing: airflow assists discharge into a 250 mL bottle for steady runs on fibrous or long materials.

Specifications

| Model | PCM-51 |

| Feed size | <25 mm |

| Final fineness | ~6.0 mm to ~0.2 mm (sieve-dependent) [NOTE TO REVIEW: confirm 0.2 mm minimum] |

| Rotor speed | 500–6000 rpm |

| Grinding set materials | Stainless steel / Heavy-metal-free steel |

| Optional sieve apertures | 0.25, 0.50, 0.75, 1.0, 2.0, 4.0, 6.0 mm |

| Collecting bottle volume | 250 mL |

| Rated power / voltage |

800 W / 110V (Optional 220VA), 50/60 Hz |

| Instrument size | 270 × 476 × 340 mm |

| Shipping/Package size | 450 × 400 × 550 mm |

| Net weight | 77lbs (35 kg) |

Optional Accessories (Call for Pricing)

- Bottom sieves: 0.25 / 0.50 / 0.75 / 1.0 / 2.0 / 4.0 / 6.0 mm apertures

- Replacement grinding set in stainless steel,

- Spare 250 mL collecting bottle

FAQs

- What fineness can I expect? With the appropriate bottom sieve, typical outputs range from ~6 mm down to ~0.2 mm. Very fibrous samples may require coarser sieves to maintain throughput.

- How do I reduce contamination risk? Choose the heavy-metal-free grinding set and keep rotor/sieve/hopper dedicated to specific matrices; quick disassembly streamlines cleaning between lots.

- Can PCM-51 process long, fibrous items? Yes—its cutting/shearing action and continuous discharge handle one-step processing of long fibrous materials without pre-cutting.

- Is speed adjustable? Yes, variable 500–6000 rpm lets you balance cutting energy and heat buildup across different materials.

- Which sieves should I stock? Common choices are 1.0–2.0 mm for general prep, 0.50–0.75 mm for finer work, and 4.0–6.0 mm for tough/fibrous feeds; exact selection depends on your method.

Warranty

A 1-year limited manufacturer warranty covering defects in materials and workmanship. For support or service authorization, provide your model/serial, purchase date, and a brief fault description. Contact us at Labgear to troubleshoot, supply parts, or coordinate repair/replacement per confirmed warranty policy.

Default Currency

Default Currency

EURO

EURO

ARA - ARGENTINA

ARA - ARGENTINA

AUD - AUSTRALIA

AUD - AUSTRALIA

BRL - BRAZIL

BRL - BRAZIL

CAD - CANADA

CAD - CANADA

CHF - SWITZERLAND

CHF - SWITZERLAND

CLP - CHILE

CLP - CHILE

CNY - CHINA

CNY - CHINA

CZK - CZECH REPUBLIC

CZK - CZECH REPUBLIC

DKK - DENMARK

DKK - DENMARK

GBP - GREAT BRITAIN

GBP - GREAT BRITAIN

IDR - INDONESIA

IDR - INDONESIA

ILS - ISRAEL

ILS - ISRAEL

INR - INDIA

INR - INDIA

JPY -JAPAN

JPY -JAPAN

KRW - SOUTH KOREAN REPUBLIC

KRW - SOUTH KOREAN REPUBLIC

MXN - MEXICO

MXN - MEXICO

MYR - MALAYSIA

MYR - MALAYSIA

NOK - NORWAY

NOK - NORWAY

NZD - NEW ZEALAND

NZD - NEW ZEALAND

PAB - PANAMA

PAB - PANAMA

PHP - PHILIPPINES

PHP - PHILIPPINES

PKR - Pakistan

PKR - Pakistan

PLN - POLAND

PLN - POLAND

RUB - RUSSIA

RUB - RUSSIA

SAR - SAUDI ARABIA

SAR - SAUDI ARABIA

SEK - SWEDEN

SEK - SWEDEN

SGD - SINGAPORE

SGD - SINGAPORE

THB - THAILAND

THB - THAILAND

TRY - TURKEY

TRY - TURKEY

TWD - TAIWAN

TWD - TAIWAN

UAH - UKRAINE

UAH - UKRAINE

ZAR - SOUTH AFRICA

ZAR - SOUTH AFRICA