Loading... Please wait...

Loading... Please wait...- Home

- Vacuum Technology

- Pumps

- VacuuBrand MZ Series Two Stage Diaphragm Vacuum Pumps

VacuuBrand MZ Series Two Stage Diaphragm Vacuum Pumps

Product Description

VacuuBrand's MZ series two stage diaphragm vacuum pumps operate oil-free, whisper quiet, reliably, and require very little service. The two-stage design provides a combination of high pumping speed and low ultimate vacuum, making them ideal for high performance low vacuum laboratory and industrial applications.

Applications

-

Evacuation,

-

Evaporation and pumping of gases and vapors in chemical,

-

Biological and Pharmaceutical Laboratories.

-

Rotary evaporators,

-

Vacuum filtration,

-

Solid phase extraction

-

Vacuum concentrators,

-

Gel dryers,

-

Vacuum drying ovens.

Features

-

Wide choice of options and configurations provide ideal solutions for chemistry vacuum systems, including corrosive chemistry compatible pumps, one or two port design, with accessories like inlet catchpot and/or solvent recovery, along with speed control and displays options.

-

Operate absolutely oil free to eliminate this source of contamination,

-

Drive space is hermetically sealed from the pumping chamber to protect mechanical parts from corrosion.

-

Exceptionally long diaphragm life and a maintenance-free drive system for very long service intervals and a low lifetime cost-of-ownership.

-

Ideal for clean applications as there are no sliding components in the gas path, so operates completely free of abrasion eliminating most of the particulate impurities and contamination frequently generated inside of scroll or piston pump,

-

Standard non-chemistry models use highly flexible FKM double diaphragms with fabric reinforcement to improve long term stability,

-

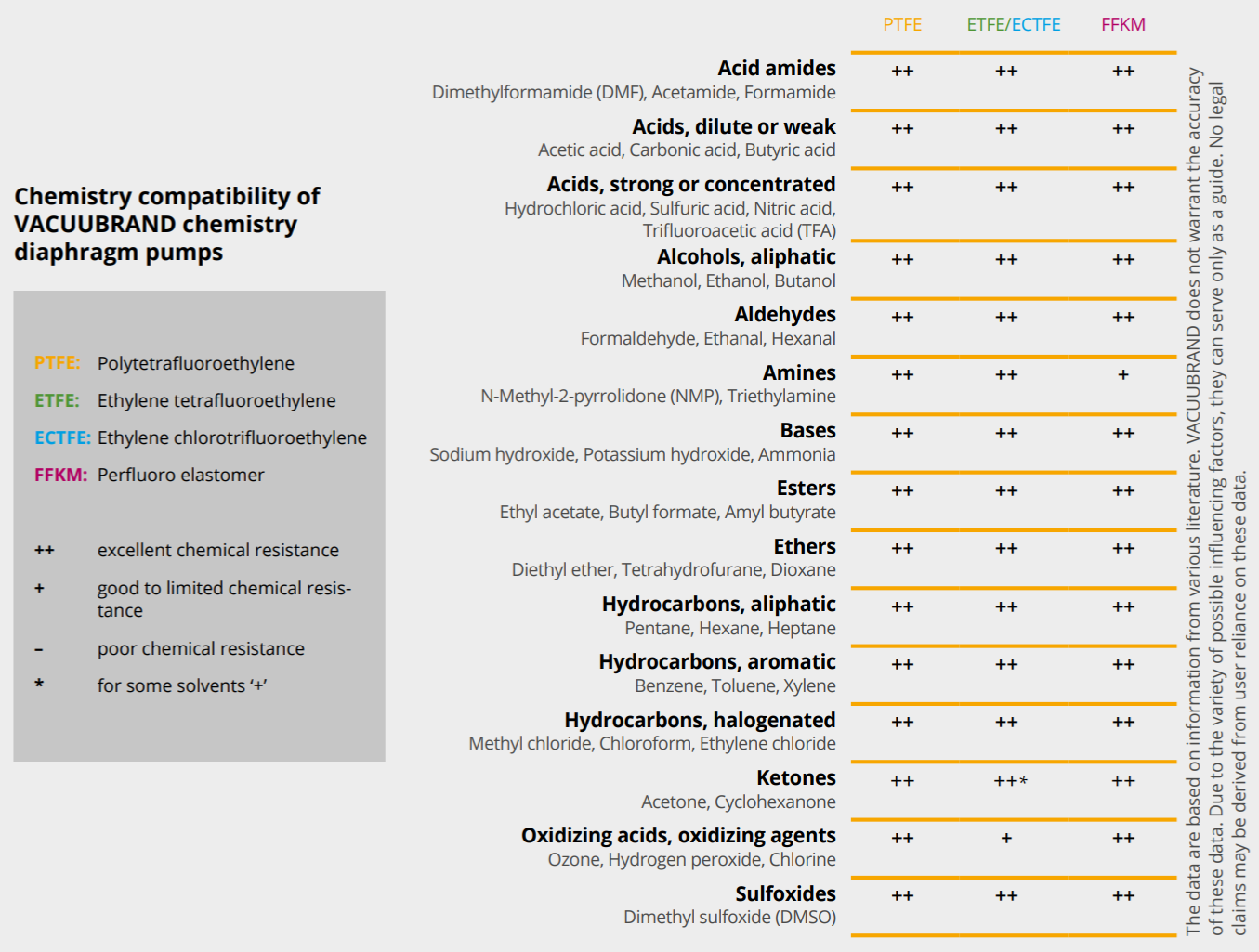

Chemistry models with “C” suffix use perfluoro elastomer (PTFE) and aluminum for all wetted materials to increase reliability and operating life when using corrosive chemicals. This makes them ideal for pumping of aggressive gases and vapors:

-

PTFE sandwich diaphragms and valves,

-

Internal tubing and fittings made of PTFE/ETFE/ECTFE compounds

-

Exceptional diaphragm lifetimes with ultra-durable PTFE sandwich design

-

Head cover and clamping disc made of fluoro compounds with stability core for unsurpassed long-term performance,

-

Whisper quiet and very low vibration for improved working environment and low disturbance of benchtop applications,

-

Compact design requires minimal benchtop space,

-

Each vacuum connection is provided with a manual flow control valve to regulate the effective pumping speed, and reliable check valves prevent interference between applications.

-

New features of "NT" designated models:

-

Patented drive system for extra quiet, ultra-low-vibration operation,

-

Patented valve mounting system to simplify service access,

-

Smooth surfaces for easy cleaning,

-

Innovative connections in the patented NT models ensure very low leak rates for excellent flow rates under vacuum and long-term performance stability, even after thousands of hours of service,

-

The optional Vacuu-Select VARIO® Controller (+VARIO, or "select") is an integrated vacuum controller which provides an easy-to-use, application based interface that covers all common lab applications. It provides precise and automatic vacuum control to save time and avoid sample loss, with precise control of the vacuum level to achieve unparalleled process control, even with an open gas ballast valve,

-

Sensors to ensure a trouble free evaporation without superheating solvents, even low or high boiling ones. Detects boiling pressure and automatically adjusts the pumping speed to maintain solvent evaporation process control, resulting in optimal process times, minimal noise, maximum process efficiency, with low energy consumption and improved service intervals for wear parts like diaphragms and valves.

-

Use manual set-point-control for simple processes,

-

Run fully automated distillations,

-

Manual set-point control for simple processes,

-

Application, desired vacuum, and other parameters can also be combined or controlled individually.

-

Predefined applications simplify laboratory work and training,

-

Create your own application with simple drag-and-drop editing using graphical user interface,

- Optional manual vacuum regulator valve with dial gauge for adjustment of pumping speed and ultimate vacuum,

-

The MZ 1C pump is equipped with a gas ballast valve for continuous condensate purge increasing the pumping capability of condensable vapors. It features slim design for space-saving installation and good vacuum performance.

-

MZ 2D NT- All parts of pump in contact with pumped media are made of aluminum, stainless steel and selected plastics, allowing a wide range of applications for non-corrosive gases.

-

Pumping units available for simultaneous operation of two independent vacuum applications, with reliable check valves to prevent interference between applications::

-

MZ 2C NT +AK SYNCHRO+EK provides manually controlled vacuum for both ports.

-

The PC 500 series utilize an electronic controller to provide an economical, compact solution for control of two vacuum ports:

-

The PC 510 - a single electronic controller for both vacuum ports,

-

The PC 511 - a single electronic controller for one vacuum port and an independent manual controller on the second port.

-

The PC 520 - dual independent electronic controls for both vacuum ports.

-

Optional "+D" analog vacuum display,

- Most pumps approved for ATEX equipment category 3 in the vapor path, with "EX" versions available for category 2 applications, (For more information call us at 888-222-2935.)

Specifications

-

Two stage, two head design,

-

Ambient Temp. Range (Operation): 10°C - 40°C (50°F to 104°F),

-

Ambient Temp. Range (Storage): -10°C - 60°C (14°F to 140°F),

-

Relative Humidity (Operation): 30% - 85%, non-condensing,

-

Max. altitude: 2000M / 6500ft,

-

Ingress Protection class (IEC 529): IP 40 (Exception: MZ 2C NT VARIO is rated IP 20),

- Motor protection : thermal cutout, manual reset,

-

Rated Motor RPM @ 50/60 Hz (no load): 1500/1800,

-

Rated Motor Power:

-

MZ 1 based units @ 60W

-

MZ 2 based systems @ 180W,

-

MZ 2 based systems with Vario @ 530W,

-

NRTL certification: Canada and the USA,

-

CE Certification: EN61010-1,

-

ATEX Certification: II 3/- G IIC T3 X (Internal Atm., 230V),

-

Performance:

| P/N | Model | Max. pumping speed, 50/60 Hz | Ultimate vac. (abs.)(mbar) | Ultim. vac. (abs.) with gas ballast (mbar) |

| BT 20724103 | MZ 1C | 0.75 / 0.9 m³/h | 12 | 20 |

| BT 20732303 | MZ 2 NT | 2.0 / 2.3 m³/h | 7 | n/a |

| BT 20732203 | MZ 2D NT | 2.3 / 2.5 m³/h | 4 | n/a |

| BT 20732303 | MZ 2C NT | 2.0 / 2.3 m³/h |

7 |

12 |

| BT 20732503 | MZ 2C NT +2AK | |||

| BT 20732603 | MZ 2C NT +AK+EK | |||

| BT 20732803 | MZ 2C NT +AK SYNCHRO+EK | |||

| BT 20732703 | MZ 2C NT +AK+M+D | |||

| BT 20733003 | PC 101 NT | |||

| BT 20733103 | PC 510 NT | |||

| BT 20733203 | PC 511 NT | |||

| BT 20733303 | PC 520 NT | |||

| BT 20732403 | MZ 2C NT VARIO | 2.8 m³/h |

-

Maximum back pressure: 1.1 bar, abs.

-

Pump Speed (@60Hz) for 10 Liter Volume:

MZ 1C

MZ 2C NT

MZ 2D NT

PC101 NT

PC 510 / PC 511 / PC 520 Models

PC 3002 Vario Select & MZ 2C NT Vario Select Models (@230V)

-

Inlet Hose connection: DN 8-10 mm,

-

Outlet Hose connection: DN 8-10 mm,

- Except MZ 2D NT:

| Inlet connection | small flange KF DN 16 |

| Outlet connection | Silencer / G1/4" |

-

Coolant Connection (as available): 2x DN 6-8 mm

-

Dimensions and Weight:

| P/N | Model | Dimensions (LxWxH, mm), approx. | Weight, approx. |

| BT 20724103 | MZ 1C | 312 x 121 x 170 | |

| BT 20732303 | MZ 2C NT | 243 x 243 x 198 | 11.1 kg |

| BT 20732503 | MZ 2C NT +2AK |

Find Similar Products by Category

Currency Converter

Choose a currency below to display product prices in the selected currency.

-

Default Currency

Default Currency

-

EURO

EURO

-

ARA - ARGENTINA

ARA - ARGENTINA

-

AUD - AUSTRALIA

AUD - AUSTRALIA

-

BRL - BRAZIL

BRL - BRAZIL

-

CAD - CANADA

CAD - CANADA

-

CHF - SWITZERLAND

CHF - SWITZERLAND

-

CLP - CHILE

CLP - CHILE

-

CNY - CHINA

CNY - CHINA

-

CZK - CZECH REPUBLIC

CZK - CZECH REPUBLIC

-

DKK - DENMARK

DKK - DENMARK

-

GBP - GREAT BRITAIN

GBP - GREAT BRITAIN

-

IDR - INDONESIA

IDR - INDONESIA

-

ILS - ISRAEL

ILS - ISRAEL

-

INR - INDIA

INR - INDIA

-

JPY -JAPAN

JPY -JAPAN

-

KRW - SOUTH KOREAN REPUBLIC

KRW - SOUTH KOREAN REPUBLIC

-

MXN - MEXICO

MXN - MEXICO

-

MYR - MALAYSIA

MYR - MALAYSIA

-

NOK - NORWAY

NOK - NORWAY

-

NZD - NEW ZEALAND

NZD - NEW ZEALAND

-

PAB - PANAMA

PAB - PANAMA

-

PHP - PHILIPPINES

PHP - PHILIPPINES

-

PKR - Pakistan

PKR - Pakistan

-

PLN - POLAND

PLN - POLAND

-

RUB - RUSSIA

RUB - RUSSIA

-

SAR - SAUDI ARABIA

SAR - SAUDI ARABIA

-

SEK - SWEDEN

SEK - SWEDEN

-

SGD - SINGAPORE

SGD - SINGAPORE

-

THB - THAILAND

THB - THAILAND

-

TRY - TURKEY

TRY - TURKEY

-

TWD - TAIWAN

TWD - TAIWAN

-

UAH - UKRAINE

UAH - UKRAINE

-

ZAR - SOUTH AFRICA

ZAR - SOUTH AFRICA