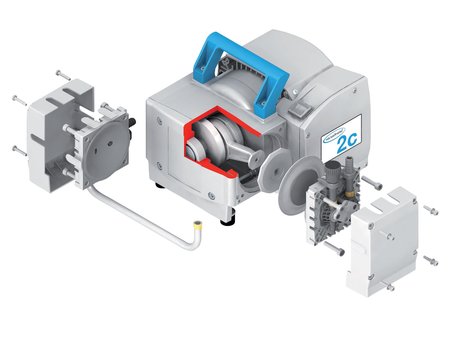

Product Description

VacuuBrand's ME series Single Stage Diaphragm Vacuum Pumps operate oil-free, whisper quiet, reliably, and require very little service, making them ideal for laboratory and industrial applications. Made with long life diaphragms and a drive space which is hermetically sealed from the pumping chamber to protect mechanical parts from corrosion. These compact vacuum pumps provide very high performance from a high pumping chamber volume relative to the minimal dead space. These single-stage diaphragm pumps will achieve as much as 70 mbar (absolute) vacuum.

Applications

-

Rotary evaporators :

-

Universal chemical resistance for any solvent combination,

-

Vacuum filtration

-

Solid phase extraction

Features

-

Highly flexible FKM double diaphragms with fabric reinforcement improves long term stability and ensures an extremely long diaphragm lifetime,

-

Operate absolutely oil free to eliminate this source of contamination,

-

No sliding components in the gas path to operate completely free of abrasion for a long service intervals and elimination of most of the particulate impurities and contamination frequently generated inside of scroll or piston pump, making them ideal for clean applications.

-

Most pumps approved for ATEX equipment category 3 in the vapor path, with "EX" versions available for category 2 applications, (Call us for additional information.)

- Sensors ensure a trouble free evaporation without superheating solvents, even low or high boiling ones,

-

Top mounted power switch is convenient, quick, and simple to use,

-

VARIO® option provides precise and automatic vacuum control to save time and avoid sample loss,

-

Whisper quiet and very low vibration for improved working environment and low disturbance of benchtop applications,

-

Compact design requires minimal benchtop space,

-

High reliability from maintenance-free drive system and proven long life diaphragm,

-

Innovative connections in the patented NT models ensure very low leak rates for excellent flow rates under vacuum and long-term performance stability, even after thousands of hours of service,

-

Chemical "C" type ideal for pumping of aggressive gases and vapors using PTFE and aluminum for all wetted materials:

-

PTFE sandwich diaphragms and valves made of perfluoro elastomer or PTFE

-

Internal tubing and fittings made of PTFE/ETFE/ECTFE compounds

-

Exceptional diaphragm lifetimes with ultra-durable PTFE sandwich design

-

Head cover and clamping disc made of fluoro compounds with stability core for unsurpassed long-term performance

-

Very long service intervals for low lifetime cost-of-ownership

-

New features of "NT" designated models:

-

Patented drive system for extra quiet, ultra-low-vibration operation,

-

Patented valve mounting system to simplify service access,

-

Smooth surfaces for easy cleaning,

-

Sealing system provides reduced leakage rates for improved ultimate vacuum.

Specifications

| Model | ME 1/1C | ME 2 NT/2C NT | ME 4 NT/4C NT | ME 8 NT/8C NT | ME 16 NT/16C NT |

| Diaphragm Heads | 1 | 1 | 2 | 4 | 8 |

| Max. Pump Speed (M3/h @ 50/60 Hz) | 0.7 / 0.85 | 2.0 / 2.2 | 4.0 / 4.4 | 7.3 / 8.1 | 16.4 / 18.4 |

| Max. Pump Speed (CFM @ 50/60 Hz) | 0.4 / 0.5 | 1.2 / 1.3 | 2.4 / 2.6 | 4.3 / 4.8 | 9.7 / 10.8 |

| Ultimate Vacuum (mbar, abs.) | 100 | 70 | 70 | 70 | 70 |

| Max. back pressure (bar, abs.) | 1.1 | 2 | 2 | 2 | 1.1 |

| Rated Motor Power (kW) | 0.04 | 0.18 | 0.25 | 0.44 | |

| Max. Noise (per EN ISO 2151:2004 and EN ISO 3744:1995 @230V/50Hz) | 45 dB(A) | 54 dB(A) | |||

|

|

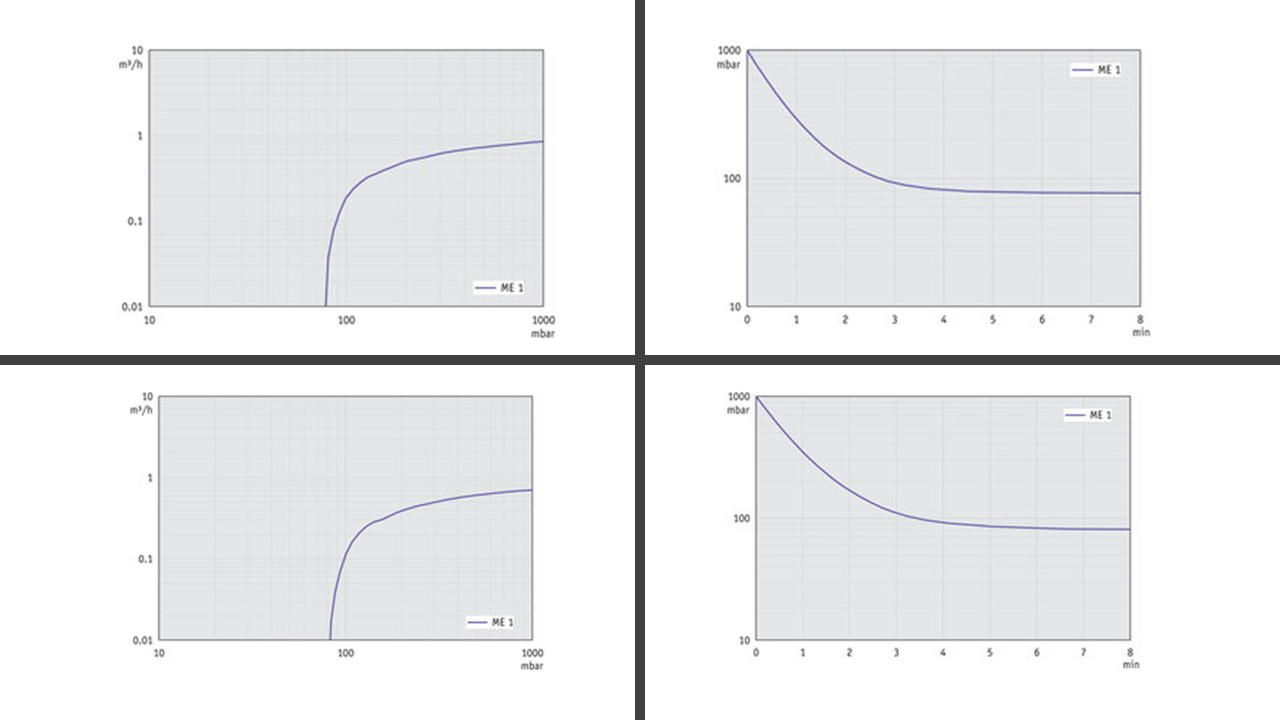

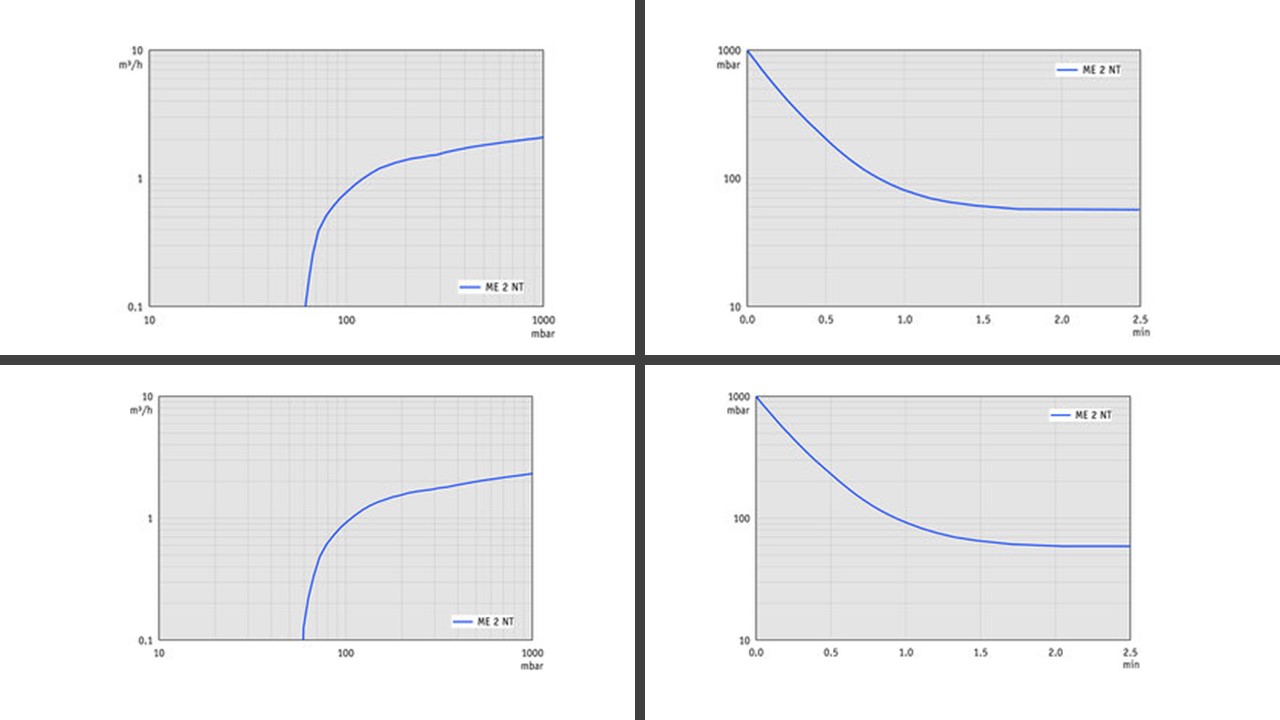

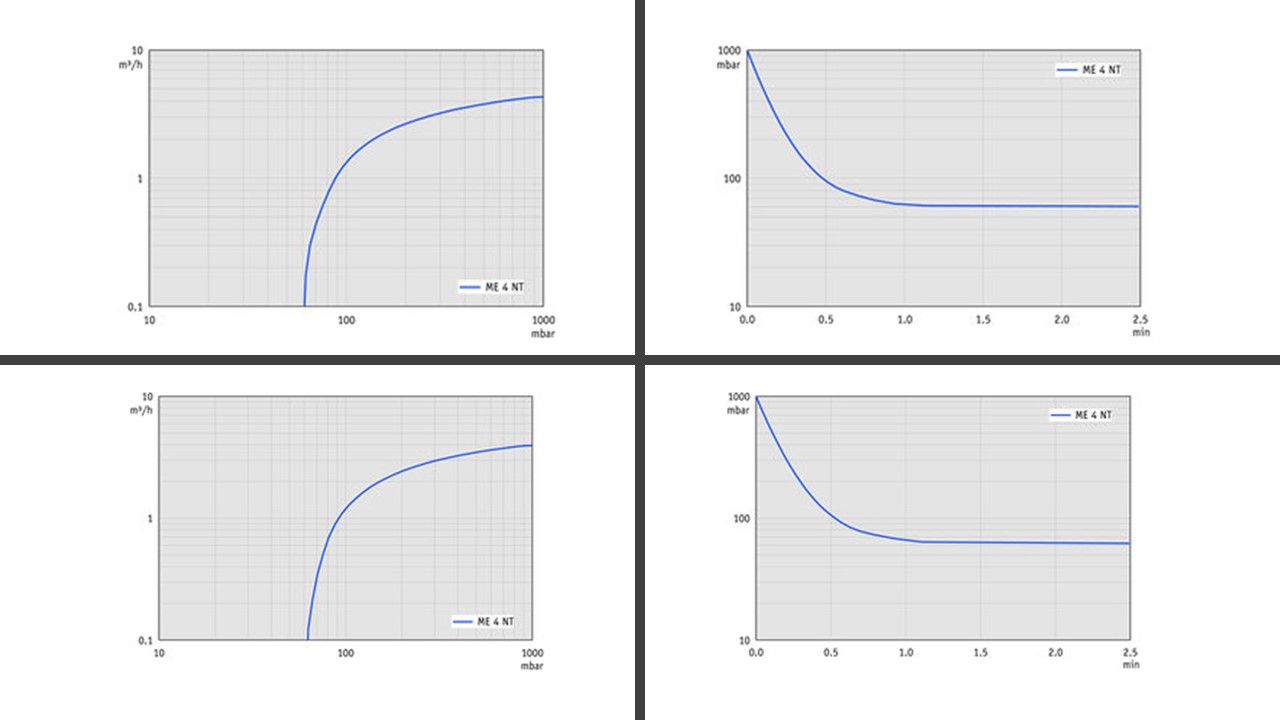

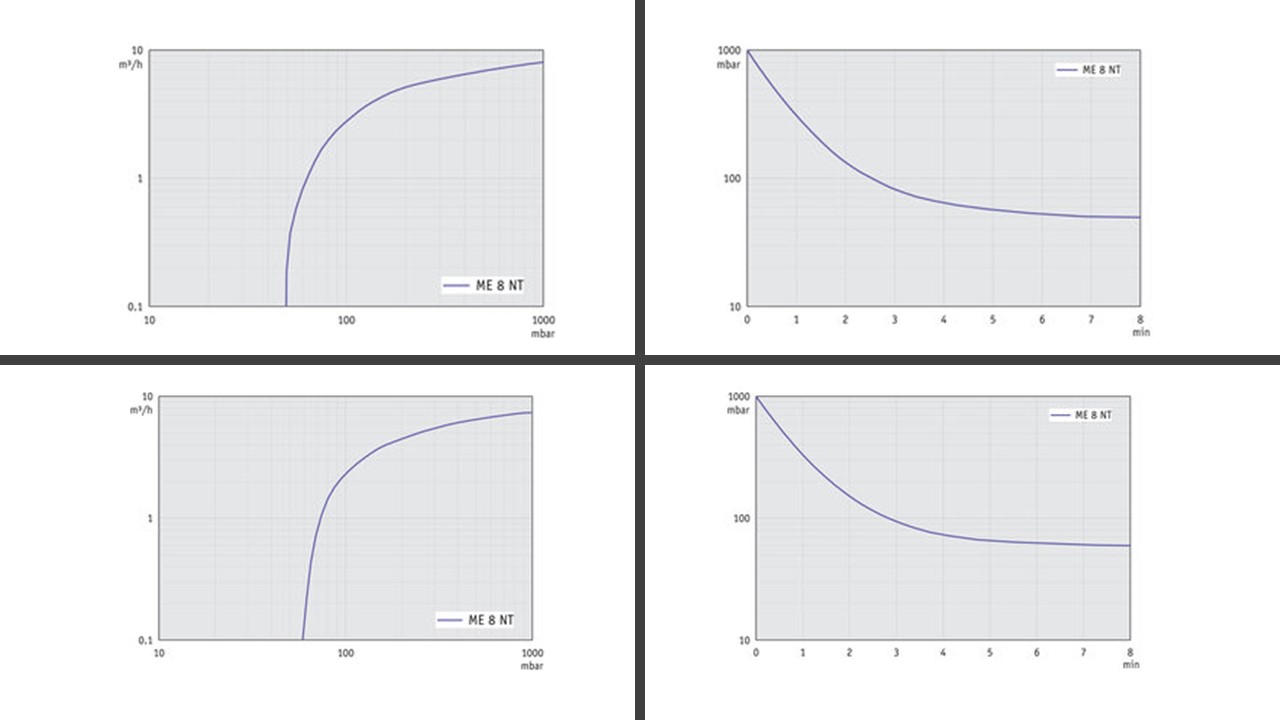

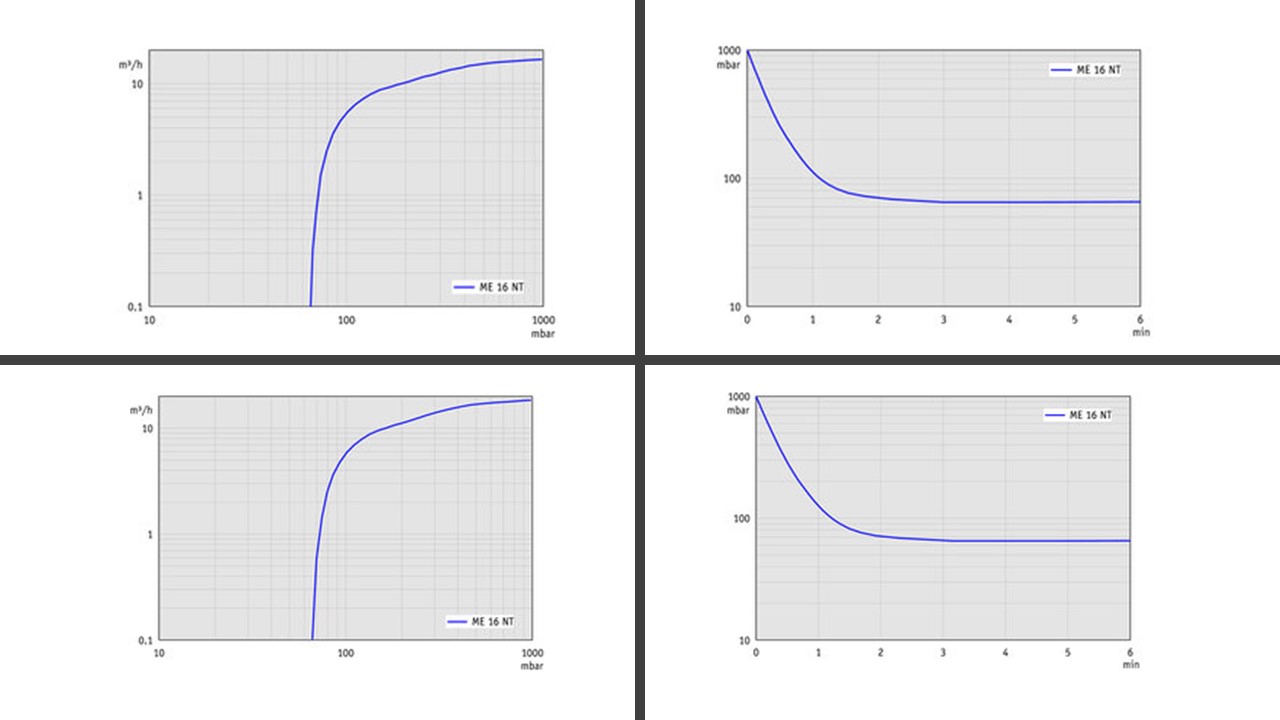

- Pump Speed by input power, for 10 Liter Volume:

60 Hz ------------- 50 Hz

- ME 1

- ME 2 NT

-

ME 4 NT

- ME 8 NT

- ME 16 NT

-

Rated Motor RPM @ 50/60 Hz (no load): 1500/1800

-

Motor protection : thermal cutout, manual reset

-

Protection class (IEC 529): IP 40

-

Ambient Temp. Range (Operation): 10°C - 40°C (50°F to 104°F)

-

Ambient Temp. Range (Storage): -10°C - 60°C (14°F to 140°F)

-

Relative Humidity (Operation): 30% - 85%, non-condensing

-

Max. altitude: 2000M / 6500ft

-

NRTL certification: Canada and the USA

-

CE Certification: EN61010-1

-

ATEX Certification: II 3/- G IIC T3 X (Internal Atm., 230V)

-

Hose connections:

-

- Models

Inlet Outlet ME 1 Hose nozzle DN 6-10 mm Silencer / G1/8" ME 1C Hose nozzle DN 8-10 mm Hose nozzle DN 8-10 mm ME 2 NT Hose nozzle DN 8-10 mm Silencer / G1/4" ME 2C NT Hose nozzle DN 8-10 mm Hose nozzle DN 8-10 mm ME 4 NT Hose nozzle DN 8-10 mm Silencer / G1/4" ME 4C NT Hose nozzle DN 8-10 mm Hose nozzle DN 8-10 mm ME 8 NT Hose nozzle DN 8-10 mm 2 x silencer / G1/4" ME 8C NT Hose nozzle DN 8-10 mm Hose nozzle DN 8-10 mm ME 16 NT small flange KF DN 25 Silencer / G1/2" ME 16C NT small flange KF DN 25 Hose nozzle DN 15 mm

-

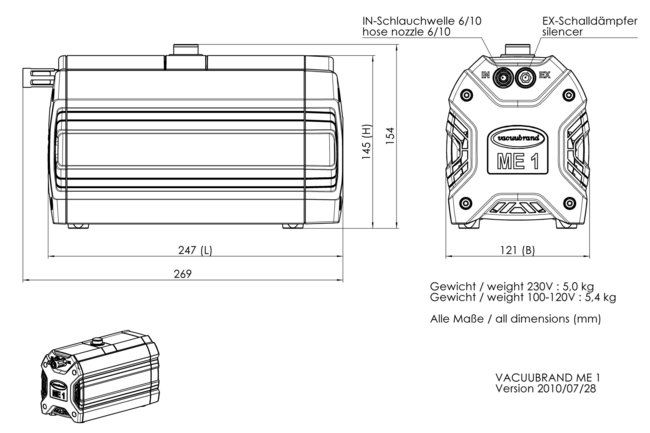

ME 1, ME 1C Physical Dimensions

-

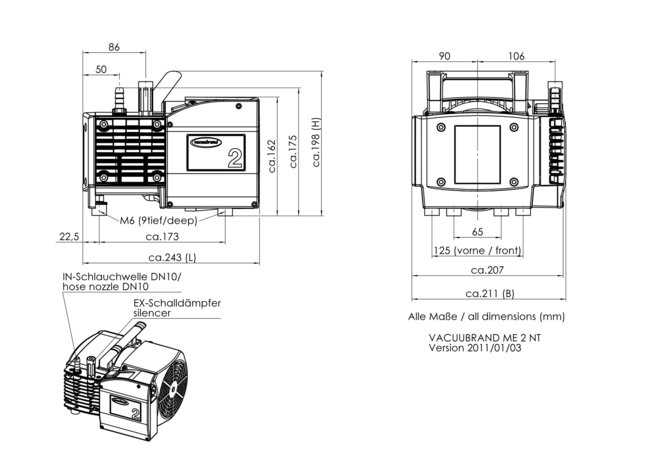

ME 2 NT Physical Dimensions

-

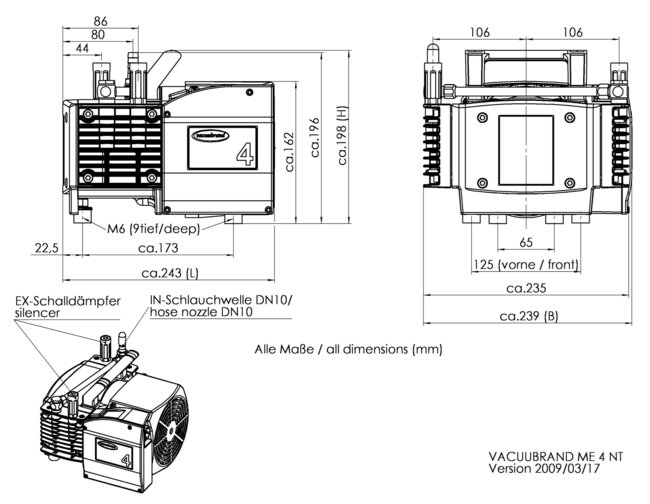

ME 4 NT Physical Dimensions

-

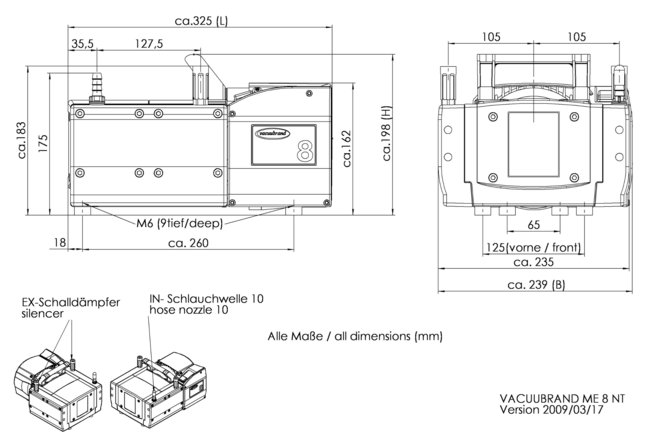

ME 8 NT Physical Dimensions

-

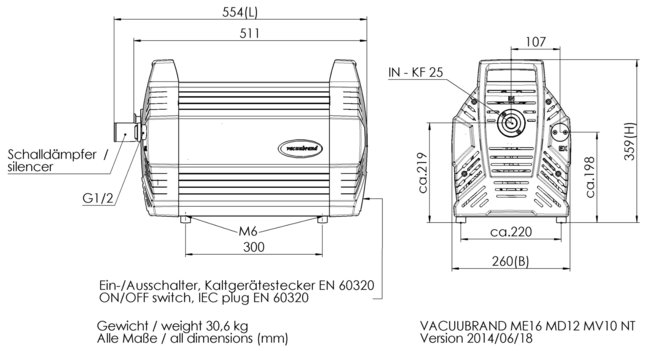

ME 16 NT Physical Dimensions

Optional Accessories (Call for Pricing)

-

ME 1

-

Rubber vacuum tubing DN 6 mm (20686000)

-

Rubber vacuum tubing DN 8 mm (20686001)

-

Vacuum regulator valve unit for ME 1 (20696842)

-

ME 2 NT

-

VACUU·LAN® Mini-Network (22614455)

-

Vacuum regulator valve with manometer (20696840)

-

Rubber vacuum tubing DN 8 mm (20686001)

-

ME 4 NT

-

Vacuum regulator valve with manometer (20696840)

-

VACUU·LAN® Mini-Network (22614455)

-

Rubber vacuum tubing DN 8 mm (20686001)

-

ME 4R NT

-

Rubber vacuum tubing DN 8 mm (20686001)

-

Manometer

-

ME 8 NT - Rubber vacuum tubing DN 8 mm (20686001)

-

ME 16 NT

-

Stainless steel tubing KF DN 25 (1 meter: 20673337)

-

Hose nozzle DN 15 mm / G1/2" (20642472)

-

Small flange KF DN 16 / G1/2" (20672101)

---

Default Currency

Default Currency

EURO

EURO

ARA - ARGENTINA

ARA - ARGENTINA

AUD - AUSTRALIA

AUD - AUSTRALIA

BRL - BRAZIL

BRL - BRAZIL

CAD - CANADA

CAD - CANADA

CHF - SWITZERLAND

CHF - SWITZERLAND

CLP - CHILE

CLP - CHILE

CNY - CHINA

CNY - CHINA

CZK - CZECH REPUBLIC

CZK - CZECH REPUBLIC

DKK - DENMARK

DKK - DENMARK

GBP - GREAT BRITAIN

GBP - GREAT BRITAIN

IDR - INDONESIA

IDR - INDONESIA

ILS - ISRAEL

ILS - ISRAEL

INR - INDIA

INR - INDIA

JPY -JAPAN

JPY -JAPAN

KRW - SOUTH KOREAN REPUBLIC

KRW - SOUTH KOREAN REPUBLIC

MXN - MEXICO

MXN - MEXICO

MYR - MALAYSIA

MYR - MALAYSIA

NOK - NORWAY

NOK - NORWAY

NZD - NEW ZEALAND

NZD - NEW ZEALAND

PAB - PANAMA

PAB - PANAMA

PHP - PHILIPPINES

PHP - PHILIPPINES

PKR - Pakistan

PKR - Pakistan

PLN - POLAND

PLN - POLAND

RUB - RUSSIA

RUB - RUSSIA

SAR - SAUDI ARABIA

SAR - SAUDI ARABIA

SEK - SWEDEN

SEK - SWEDEN

SGD - SINGAPORE

SGD - SINGAPORE

THB - THAILAND

THB - THAILAND

TRY - TURKEY

TRY - TURKEY

TWD - TAIWAN

TWD - TAIWAN

UAH - UKRAINE

UAH - UKRAINE

ZAR - SOUTH AFRICA

ZAR - SOUTH AFRICA